HOUSTON, TX (PRWEB) MARCH 18, 2014

APO announced today it has been issued patent No. 8,676,721 B2, dated March 18, 2014, by the United States Patent and Trademark Office. Surface equipment on the topside of oil and gas platforms, whether onshore of offshore, consists of many disparate systems and usually shows condition alarms of the operating and production equipment. These alarms can trigger extensive scheduling of maintenance, analysis and planning of equipment performance and possible replacement for peak operational performance. While these systems share alarm information, owner-operators pursuing profitability improvements are in search of solutions to eliminate costly downtime, reduce personnel on board, and more efficient handling of conditions that may cause events.

APO announced today it has been issued patent No. 8,676,721 B2, dated March 18, 2014, by the United States Patent and Trademark Office. Surface equipment on the topside of oil and gas platforms, whether onshore of offshore, consists of many disparate systems and usually shows condition alarms of the operating and production equipment. These alarms can trigger extensive scheduling of maintenance, analysis and planning of equipment performance and possible replacement for peak operational performance. While these systems share alarm information, owner-operators pursuing profitability improvements are in search of solutions to eliminate costly downtime, reduce personnel on board, and more efficient handling of conditions that may cause events.

The APO patent describes methods for integrating diverse equipment data using computer systems to filter and predict the future equipment status. The I-Platform solution uses open architecture for integration with products of multiple suppliers, and provides a low-risk implementation path and system expansion as new systems, platforms and fields are integrated with the solution. I-Platform will be used in support of downtime reduction and reliability improvement for future optimization of facility efficiency and energy consumption. It will also support the future of maintaining equipment within defined operating envelopes to provide cost savings and provide the basis for future unmanned facilities.

“Oil and Gas Owner/Operators today face extreme pressures to reduce downtime and operating costs from low oil prices and strict environmental conditions. Only APO’s patented technology solution can provide the analysis of the facility conditions to prevent future conditions and events from occurring in order to meet their goals,” said Jess Kozman, CTO of APO. “Since 2009, APO is the leader in predictive analytic solutions for the topside surface equipment and the issuance of this patent reinforces the value of our goal to reduce equipment failures for our customers.”

This is the first patent issued to APO Offshore Inc.; (APO), with other submissions from the company currently underway.

Results of the full Integrated Operations projects have been documented in over 10 individual SPE papers and include a 70% improvement in response time to the field, with fast-loop decision cycles reduced from 10 days to 5 minutes, and medium-loop asset operational reviews now performed hourly and daily rather than monthly. In addition, gas lift performance has improved by 20%, field visits and associated QSHE risk has been reduced by 70%, production has increased by three times from less than 5K to more than 15K bopd, and well uptime has improved from 60% to 80%. Since the work was performed as part of a Risk-Sharing contract, financial benefits have accrued to all participants in the program.

Results of the full Integrated Operations projects have been documented in over 10 individual SPE papers and include a 70% improvement in response time to the field, with fast-loop decision cycles reduced from 10 days to 5 minutes, and medium-loop asset operational reviews now performed hourly and daily rather than monthly. In addition, gas lift performance has improved by 20%, field visits and associated QSHE risk has been reduced by 70%, production has increased by three times from less than 5K to more than 15K bopd, and well uptime has improved from 60% to 80%. Since the work was performed as part of a Risk-Sharing contract, financial benefits have accrued to all participants in the program.

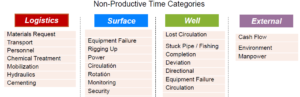

The result was an average reduction in non-productive time due to logistics of 3 days per rig per month for the field operation over 6 months. By using the operating costs per hour for both locally and internationally operated rigs, the team was able to calculate that after an initial investment of USD $630,000, primarily in personnel and training costs, the return on investment for this project was USD $23 M in the first 6 months.

The result was an average reduction in non-productive time due to logistics of 3 days per rig per month for the field operation over 6 months. By using the operating costs per hour for both locally and internationally operated rigs, the team was able to calculate that after an initial investment of USD $630,000, primarily in personnel and training costs, the return on investment for this project was USD $23 M in the first 6 months. In addition, there were benefits in rigs and personnel being able to spend more time on projects with lower risk and higher drilling success rates. The next stage of the project was to develop a business case for reducing downtime in the other categories through the use of predictive analytics applied to depth-indexed and aggregated drilling engineering data, resulting in additional projected savings of USD $5.6 M.

In addition, there were benefits in rigs and personnel being able to spend more time on projects with lower risk and higher drilling success rates. The next stage of the project was to develop a business case for reducing downtime in the other categories through the use of predictive analytics applied to depth-indexed and aggregated drilling engineering data, resulting in additional projected savings of USD $5.6 M.

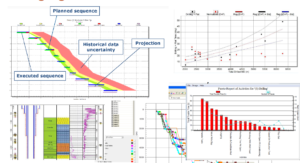

Data from rigs is transmitted in real time using WITSML (Wellsite Information Transfer Standard Markup Language) and is constantly monitored at the National Oil Company with a target to reduce the drilling duration of wells by 10% each year, and to reduce overall NPT (Non Productive Time) on a per-rig basis. The in-place system requires interoperability and cooperation between several companies and services and agreement on data governance and quality control in order to deliver actionable data. The data including LWD, MWD and Surface data are collected on the rig, aggregated, quality checked and synchronized and then transferred to the NDC (National Drilling Company) where they are accessed by a service company.

Data from rigs is transmitted in real time using WITSML (Wellsite Information Transfer Standard Markup Language) and is constantly monitored at the National Oil Company with a target to reduce the drilling duration of wells by 10% each year, and to reduce overall NPT (Non Productive Time) on a per-rig basis. The in-place system requires interoperability and cooperation between several companies and services and agreement on data governance and quality control in order to deliver actionable data. The data including LWD, MWD and Surface data are collected on the rig, aggregated, quality checked and synchronized and then transferred to the NDC (National Drilling Company) where they are accessed by a service company. Relevant data are extracted from the DDR (Daily Drilling Report) within an engineer’s data model, these data are sent and combined with the wellsite data. Using data analysis software, the results are matched against NPT in the DDR and the non-reported NPT checked for deviations. All NPT codes have been standardized (between onshore and offshore operations) and agreed by the operating companies and documented in the National Drilling Code of Practice. The final results including drilling performance against plan and real time video of rig operations are then ready for delivery to an intelligent subsurface centre for visualization and action. The system was first developed for solely operated and risked gas wells, but is being expanded to include all drilling operations in the country.

Relevant data are extracted from the DDR (Daily Drilling Report) within an engineer’s data model, these data are sent and combined with the wellsite data. Using data analysis software, the results are matched against NPT in the DDR and the non-reported NPT checked for deviations. All NPT codes have been standardized (between onshore and offshore operations) and agreed by the operating companies and documented in the National Drilling Code of Practice. The final results including drilling performance against plan and real time video of rig operations are then ready for delivery to an intelligent subsurface centre for visualization and action. The system was first developed for solely operated and risked gas wells, but is being expanded to include all drilling operations in the country. As part of the study, APO data management practitioners recommended a data governance structure with business data focal points in each of the OPCO’s, the criteria and operating requirements for a System of Record for the final drilling data, and the standardization of naming conventions to ensure data was associated with the correct borehole and for reporting of drilling events such as Rig Release Date. These recommendations were made to align with a future plan to utilize a business intelligence platform for integration and interoperability with other data initiatives in the National Oil Company such as Category Management and optimized supply chains for Oil Country Tubular Goods to service the rigs.

As part of the study, APO data management practitioners recommended a data governance structure with business data focal points in each of the OPCO’s, the criteria and operating requirements for a System of Record for the final drilling data, and the standardization of naming conventions to ensure data was associated with the correct borehole and for reporting of drilling events such as Rig Release Date. These recommendations were made to align with a future plan to utilize a business intelligence platform for integration and interoperability with other data initiatives in the National Oil Company such as Category Management and optimized supply chains for Oil Country Tubular Goods to service the rigs.